Product

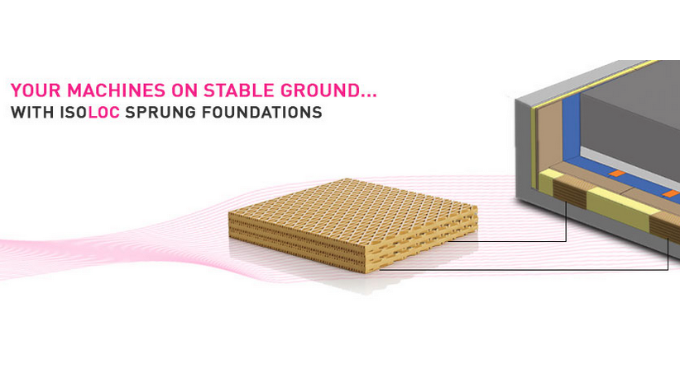

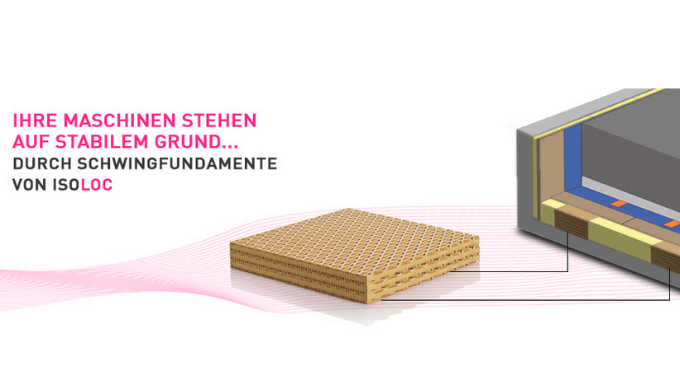

Sprung foundations

The individual design of sprung foundation insulations requires a special know-how and extensive experience. We have more than 20 years of experience in planning, calculating and realization of sprung foundations with a weight of several 1.000 kN.

Purpose of a sprung foundation

A sprung foundation insulation includes, in the broadest sense, any vibration insulation which is not installed directly under the machine but under the machine foundation. Such a machine foundation is often sunk into the ground in a foundation pit (" underfloor"), but in case of smaller sizes it could also be arranged " above floor".

Increase of the stability and torsional stiffness of a machine

Certain machines / plants require the setup on a foundation for stiffening, if a vibration insulation is intended. The elastic vibration insulation elements are integrated under the additional mass. The foundation block makes it also possible for machines without inherent stiffness to be set up with very elastic vibration insulation packs in a vibration insulated way.

Deeper bearing natural frequency of the vibration insulation

- Higher insulation rate I(f) because of the higher total mass and as a result the deeper natural frequency of the bearing at the same amount of vibration insulation elements.

- As emission protection by source insulation

e.g. for presses, punches, air hammers, printing machines, ball mills, forging machines, test-benches, turbines, broaching machines and many more. - As immission protection by receiver insulation

e.g. for measuring machines, grinding machines, microfinishing machines, microscopes as well as any vibration-sensitive machines and devices imposing highest requirements to precision.

Through the additional mass of the concrete block and the vibration insulation elements, improvements of the dynamic behaviour in comparison to a machine which is set up in a directly vibration insulated way are realized at a constant natural angular frequency. These are:

- fewer amplitudes, attached elements are stressed less (tear off),

- lesser mass forces apply on the components of the machine (longer life).