Product

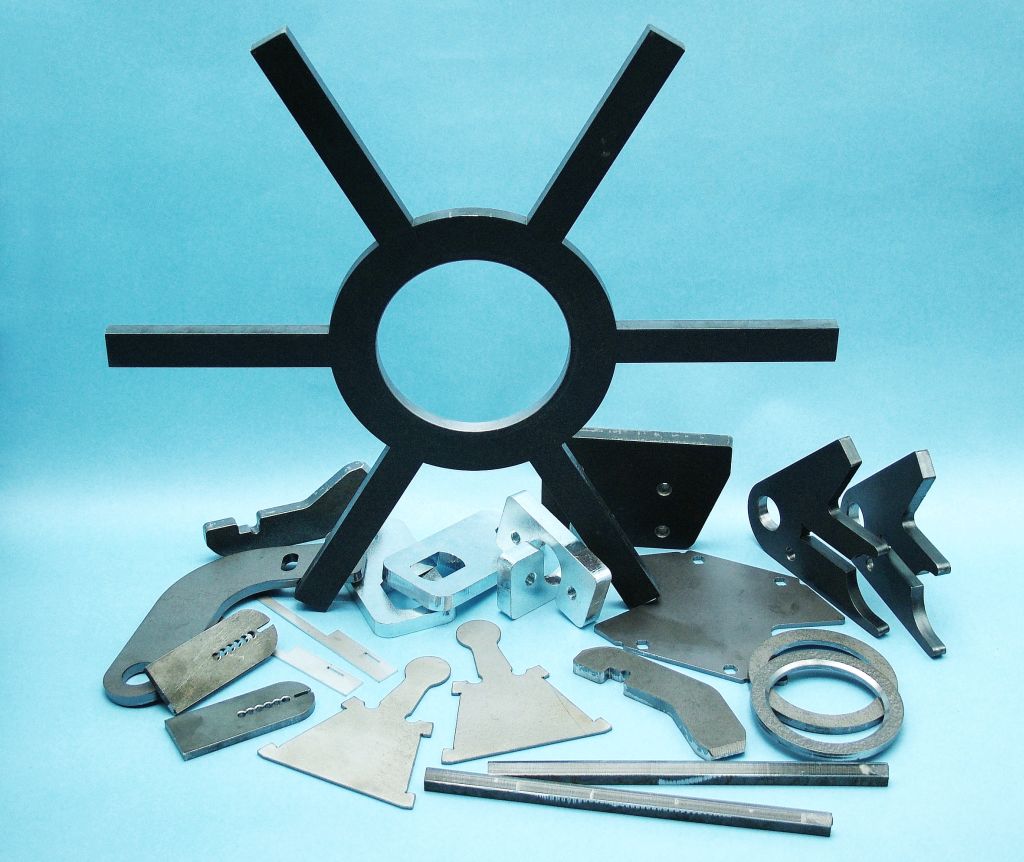

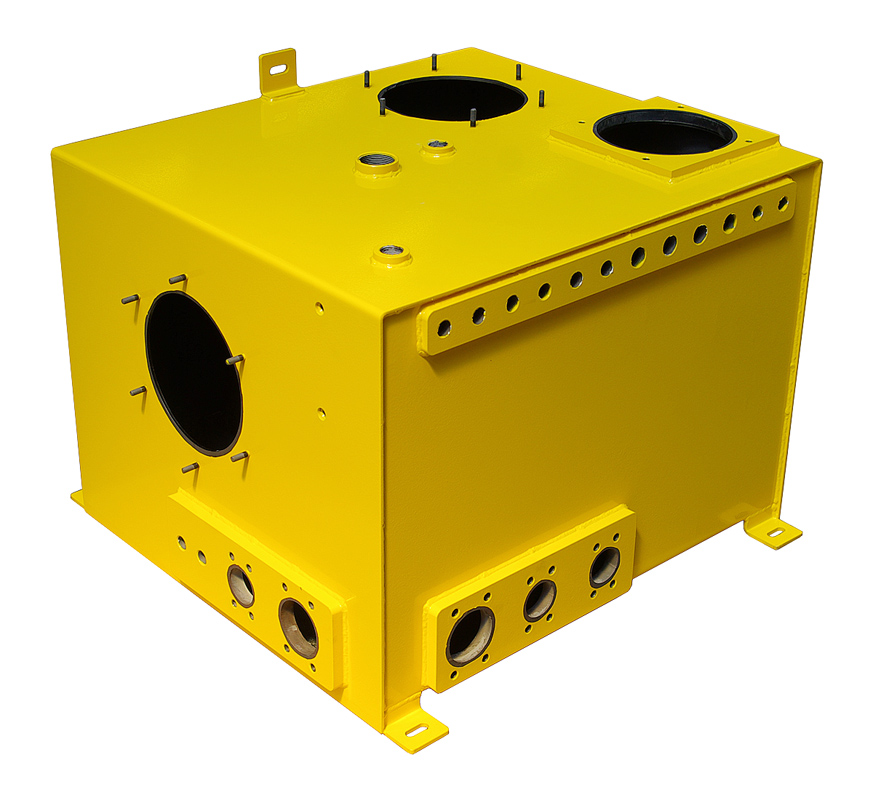

CNC pressed and bent steel and non-ferrous parts and components

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

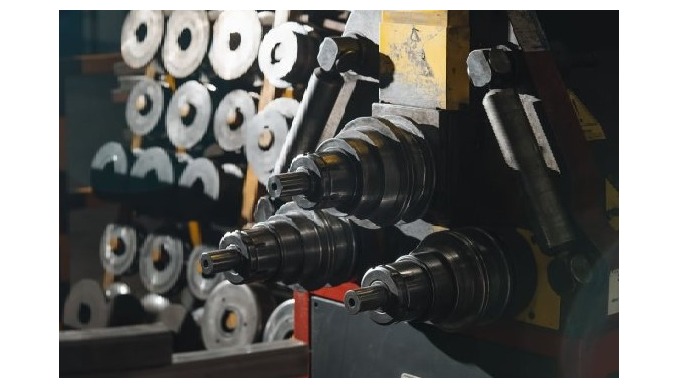

At Curvados Alzania, we specialize in cold bending of steel tubes and profiles with more than 25 years of experience in the metal forming industry. Using advanced machinery and skilled technicians, we deliver high-precision, consistent results tailored to each client’s technical needs. Our cold bending process allows us to reshape steel components at room temperature without compromising material integrity. The result is durable, smooth, and dimensionally accurate curves — ideal for demanding structural, architectural, and industrial projects. — 🔍 What Is Cold Bending? Cold bending is a metal forming process that reshapes tubes and profiles without the application of heat. This method preserves the mechanical properties of the steel, ensures tighter dimensional tolerances, and eliminates unwanted metallurgical changes. It is especially effective for creating consistent bends in medium- to large-scale structural elements. — 🛠 Materials and Steel Profiles We Bend We work with a wide range of steel materials and cross-sections, including: Round, square and rectangular steel tubes Structural profiles: IPN, IPE, UPN, HEB, HEM Custom shapes: angles, T-profiles, L-profiles, flat bars, solid bars Carbon steel, galvanized steel, stainless steel Extra-long lengths and special formats available — 🏗 Common Applications of Cold Bent Steel Structural arches and curved steel frames Railings, handrails, and ornamental metalwork Domes, pergolas, canopies, and roofing structures Bridges, tunnels, and railway infrastructure Components for machinery and industrial equipment Architectural and artistic installations

-

We have a modern bending machine-maximum sheet thickness of 0.5-2mm, maximum length of 2050mm and CNC edge presses. We make even the most advanced bends that fit in the parameters of our machines - a maximum thickness of 6mm for the adopted maximum length of 3050mm. We invite you to contact us to learn more details www.sip.krosno.pl

-

CNC milling is one of the most commonly used methods of metal, plastic and wood processing. Using different blades, you can get the most different forms in metal, plastic, plywood, wood. Thanks to CNC milling, we obtain high accuracy, precise elements, in accordance with the project. We mill sizes 2750x1500mm.

-