Product

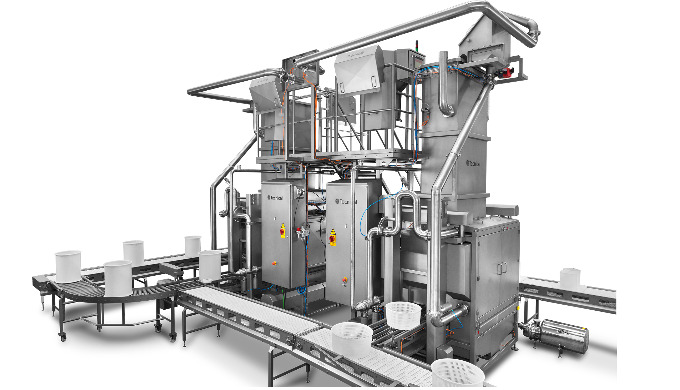

Production Lines for Pressed Cheese | Automated Technical Solutions

With decades of experience in the food processing sector and in-depth expertise in cheese technologies, we provide cutting-edge equipment for every stage of the pressed cheese production process — from curdling and molding to pressing and brining.

🧀 What is pressed cheese?

Pressed cheese is a variety where whey is partially removed by applying mechanical pressure. This process results in a denser texture, lower moisture content, and longer shelf life — typical of cheeses such as Manchego, Gouda, Emmental, or Cheddar. Precision and control at each step of the process are essential to ensure consistency and product quality.

🛠️ Our Technology for Pressed Cheese Production

Our production lines feature a modular and scalable design, adaptable to various output capacities and cheese formats. Key components include:

- Automated curdling vats with temperature and agitation control

- Optimized curd cutting and whey drainage systems

- Automatic pre-pressing and molding units

- Hydraulic cheese presses with adjustable multi-format settings

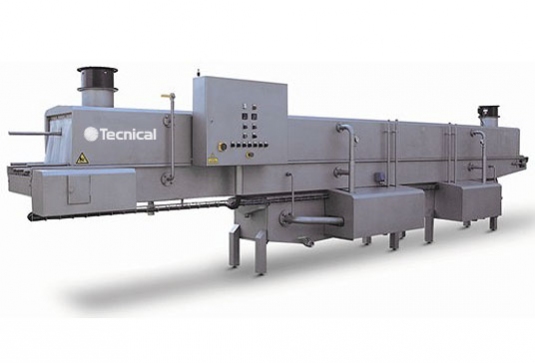

- Continuous or batch brining tunnels

- Integrated CIP cleaning systems

- Full process control and traceability via SCADA/PLC systems

- Fully automated process with minimal manual handling

- Faster production times and reduced energy consumption

- Hygienic design with food-grade stainless steel (AISI 304/316)

- Compatible with a wide range of cheeses and mold types

- Technical assistance, staff training and preventive maintenance included

We develop pressed cheese production lines for both artisanal dairies and large-scale industrial plants. Our systems are adaptable to different milk sources (cow, goat, sheep), production volumes, cheese types and automation levels.

Price of the Product

Category of the Product

Company website

Company catalogues - Tecnical Tecnología Aplicada SL