Product

Modular rack system for pallets TEXO

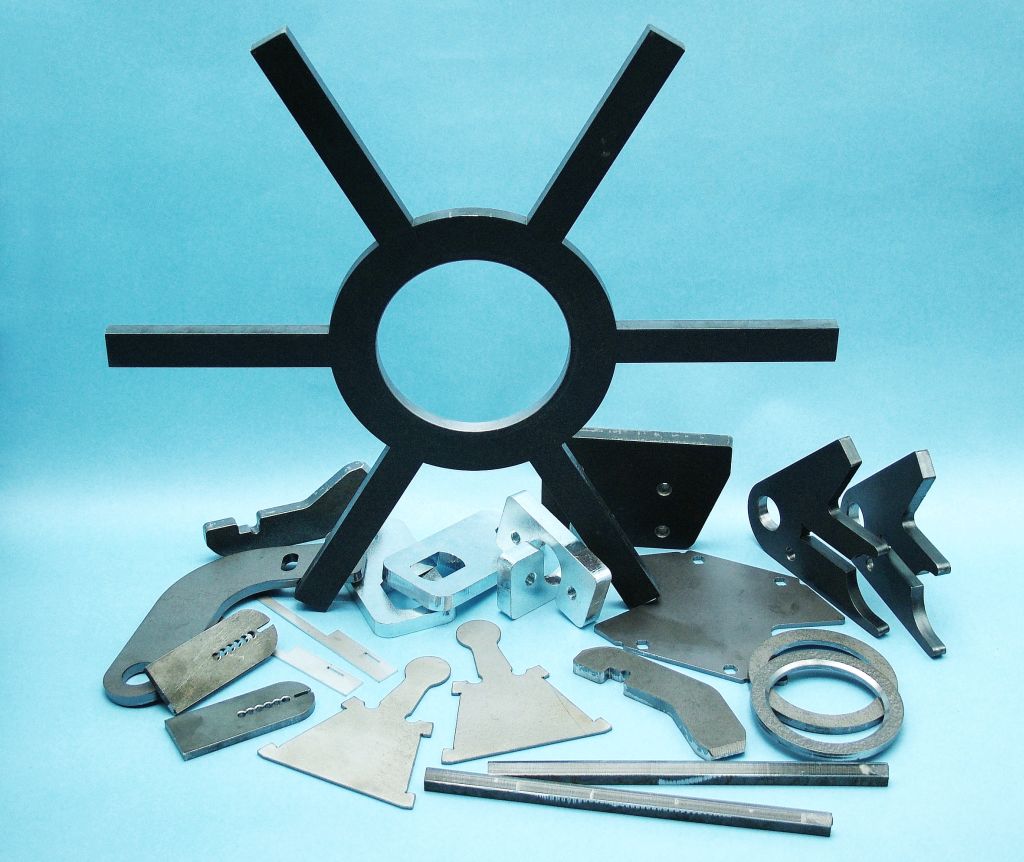

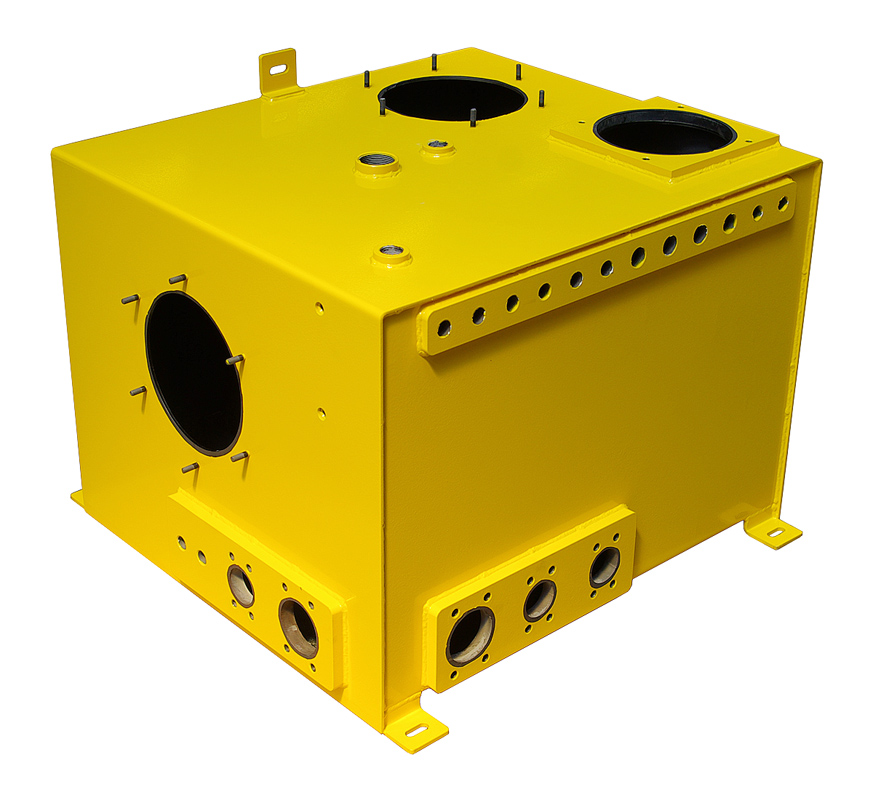

In addition to the production of sheet metal and molded parts, weldments and laser fragments, we also produce shelving for storage. Our offer includes a modular pallet racking shelf.

The TEXO modular storage rack is suitable for production facilities, warehouses, logistics centers and wherever the goods are stored on pallets. The TEXO modular pallet rack is used to store pallets from 1200x800 mm up to a size of 3900x1200 mm and consists of four basic modules that can be combined together to create the desired rack line configuration. Colored racks can be customized based on the RAL sampler.

The advantage of our modular storage rack is that the user racks the stack of individual modules as he currently needs. The actual composition and dismantling of the rack is quick and convenient.

For more information about our modular rack system for pallet storage please visit www.dendera.cz

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Deburring and Grinding RUSTEK A/S´s Timesave's grinding / deburring machine is a machine for deburring and / or grinding, plate items after cutting, cutting and similar processes, to remove any. sharp edges, burrs etc. The machine processes the workpieces by first sanding the surface with an sanding belt to remove any larger foreign elements, and then brush the edges with rotating brushes that run each way and rotate about an axis, in this way the subject is "hit" from all sides. The alternative to this machine is manual sanding, which can make a big difference in terms of which operator performs the sanding work, in addition, it can also be physically hard to sand manually. This machine helps to ensure that RUSTEK A / S always delivers a uniformly good quality, which is only possible with high-quality machining.

-

BEAD PRESS AND SHEET FOLDING Rustek has recently invested in the most modern bead presser in Denmark. This bead presser is, like our laser, of the brand LVD. The bead press is equipped with all necessary contemporary electronics to facilitate a satisfactory result. When a customer submits a schematic of a desired presing subject, it is imported to the program which Rustek uses for the bead press. Here the subject is built up completely in 3D. Then the program makes sure the pressings fit, or whether corrections need to be made. If the schematics are available in 3D (SAT/IGES), these can be imported directly and an unfolding is done directly after the finished unit, so that all parameters are controlled by the machine. When the subject is unfolded, a complete simulation of the pressing takes place. Rustek's bead presser is equipped with laser safety, which means it can run up to 300% faster in the pressing than the competition. This is due to the TURBO installed on the machine. More specifically a 50 HP motor is connected to the hydraulic unit. This in co-operation with a large oil cooling unit, makes it possible for the presser to run at this extreme speed. For more advanced subjects/projects, Rustek has the equipment for measurement of angles. This takes place by use of laser technology, where small laser-sensors measure angles during the folding process itself. They do this with no delay to the actual process, thus ensuring a minimal waste of materials and makes the use of time for test foldings and such absolute. Things that usually increase the general price range. Another thing that speeds the startup and programming of a project is the substantial database in the machine. This database not only ensures that Rustek will fold at least 99% correctly the first time. However immediate control and checking after the first fold, and subsequent updates to the database means that the chance of folding 100% correct on the first folding is increased for every folding done.

-

Precision sheet metal processing is our passion We bring sheet metal into shape. Our employees offer competence and experience in all modern processing techniques. We are also happy to provide advice - when it comes to processing issues and value for money. CUTTING AND SEPARATING Punching and laser technology with state-of-the-art machines (flatbed laser, tube laser, punch-laser combination machine) SHAPING Forming technology, such as press brakes (press brakes) and round bending up to the forming of threads, countersinks, beads and more on our punching- laser-combi machine WELDING TECHNOLOGY We master the most diverse possibilities: MIG/MAG welding, TIG welding, spot welding, hand laser welding, stud welding. FINISHING AND SURFACE A wide range of surface treatment options: powder coating, electroplating, grinding/deburring, subassembly assembly. Regardless of whether the goal is a demanding one-off production or a quality-assured series production. We adapt individually to the needs of our customers. After all, it's all about finding the best and most economical solution for your requirements. And should we not be able to master a processing technique, we have partners who we will be happy to coordinate for you.

-